MK-10 STRUCTURAL FOUNDATIONS

DO-IT-YOURSELF FOUNDATION KITS

For Steel, Wood, and Metal Structures

ENGINEER INSPECTION CERTIFICATE

Included with every form prior to pour.

MK-14 STRUCTURAL FOUNDATIONS

Resolves every issue facing a

conventional foundation.

The foundation design has been carried out by a structural professional engineer practicing for 55 years with extensive experience in the design of floating foundations. The MK5 is a patented product that complies with the Current OBC.

The “MK5 slab on grade” has actually been designed as a two-way floating slab foundation. We have designed this foundation according to Part 4 Structural, of the Ontario Building Code.

• The foundation has been designed for serviceability (serviceability limit states: restricting problems from deflection, limiting damage to the structure itself, and creep/temperature shrinkage changes).

• The forms for the foundation slab have been manufactured / designed to protect the slab and rebar positioning integrity.

DO IT YOURSELF Structural Foundation Kits

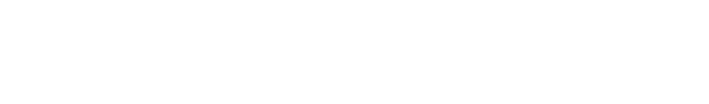

Prefabricated, ready to assemble on site by the end user, anyone with basic construction savvy can install the form, see the step-by-step animation, no skilled trades are required.

MK5 Flat Slab Foundations are above ground not 5 -6 feet below, build anywhere, flood zones, conservation areas, high static water levels, heavy rock or remote

There are plenty of trained crews available, most will travel.

” 30 x 50 x 6″ Form [ 1 skid ]

Ships Anywhere!

Do-It-Yourself

MK5 kits are designed for first time buyers, detailed manuals and inspection certificates included.

Pre-Engineered

Beam Bar Design and Permit Drawings provided by Structural Design software, fast and dead-on accurate.

Pre-Fabricated

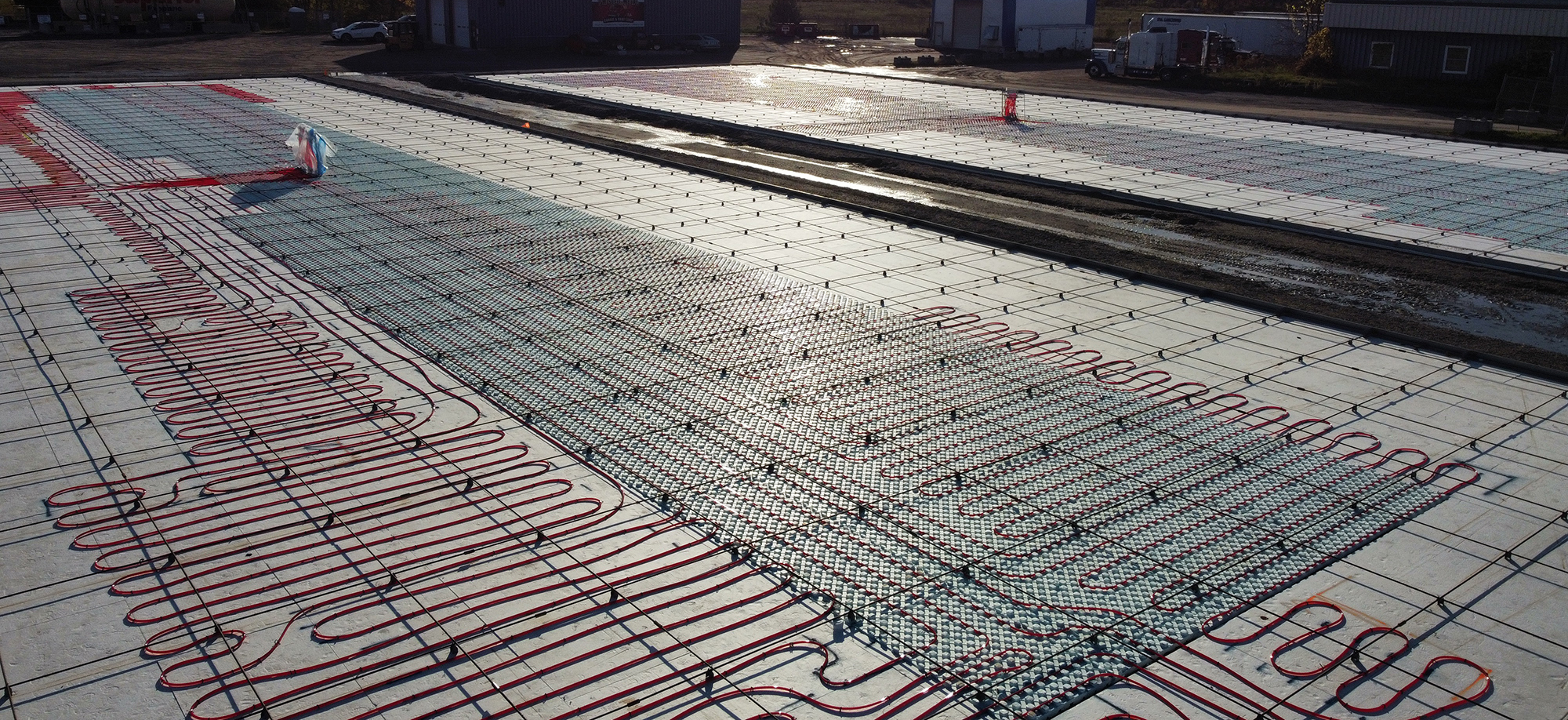

Beam Bars positioned with-in 1/4″ of Engineering specification.

Anchors

100% anchor bolt location templates with every form guarantees the correct size, location, and depth on all MK series foundations to 8”.

Site Preparation

The MK5 Foundation requires a drain base as the “bottom” of the form. Heavy excavation is not required. Not digging down into the natural soils.

Frost Protection

MK5 flat-slab foundations provide an easy solution to frost penetration, simply push the line of frost away from the slab.

Special Installs

MK5 flat-slab foundations – Do-IT-Yourself – Special Installs.

Contact us for more information about your project.